Nuclear Research and Industry

G-MET Ingénierie is a design office that has been heavily involved in research and the nuclear industry since it was founded in 2014.

This sector accounts for the majority of studies handled by G-MET Ingénierie, which has developed recognised expertise in the field.

Our main nuclear customers

Our team of engineers is experienced and aware of the constraints imposed by nuclear safety. Since its creation, G-MET Ingénierie has been heavily involved in nuclear fission projects (RJH experimental reactor, experimental nuclear devices, PWR reactors, SMR) and fusion projects (ITER reactor).

Research organisations

We work with leading research centres to develop advanced simulation models, support experimental innovation and participate in fusion and fission projects.

Operators

We support nuclear power plant operators in performance optimisation, equipment safety and regulatory studies.

Project owners and engineers

We provide support for projects involving new installations or decommissioning, by contributing our expertise in structural calculations, CFD and design codes.

Research organisations

We work with leading research centres to develop advanced simulation models, support experimental innovation and participate in fusion and fission projects.

Operators

We support nuclear power plant operators in performance optimisation, equipment safety and regulatory studies.

Project owners and engineers

We provide support for projects involving new installations or decommissioning, by contributing our expertise in structural calculations, CFD and design codes.

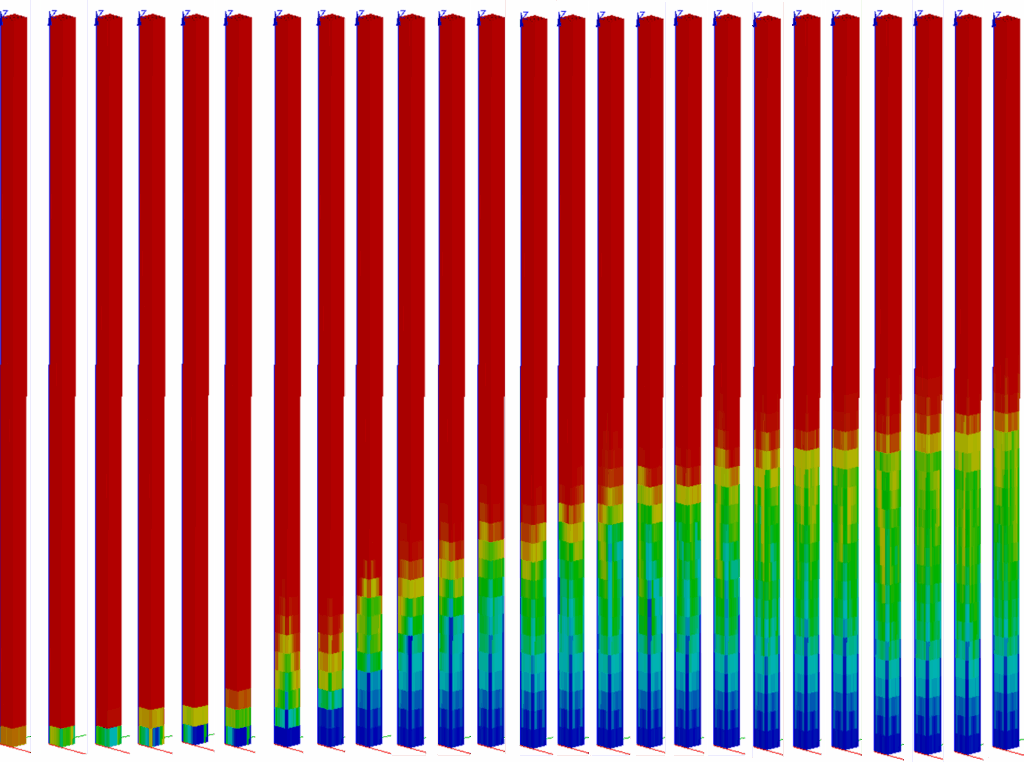

Blow-out simulation - Two-phase flow

This video illustrates an example of the application of incompressible two-phase flow for the nuclear industry and research. The aim of this simulation was to calculate the transient evacuation of water from a cooling circuit. The simulation is quite large, with a mesh size of approximately 52 million cells. In addition, data storage accounted for more than 40 To.

The simulation is carried out using a solver two-phase especially developed with our preferred tools: OpenFOAM.

Application types

We have in-depth knowledge of thermohydraulic and thermomechanical issues in the nuclear sector. For example, we have worked on various projects such as:

REP

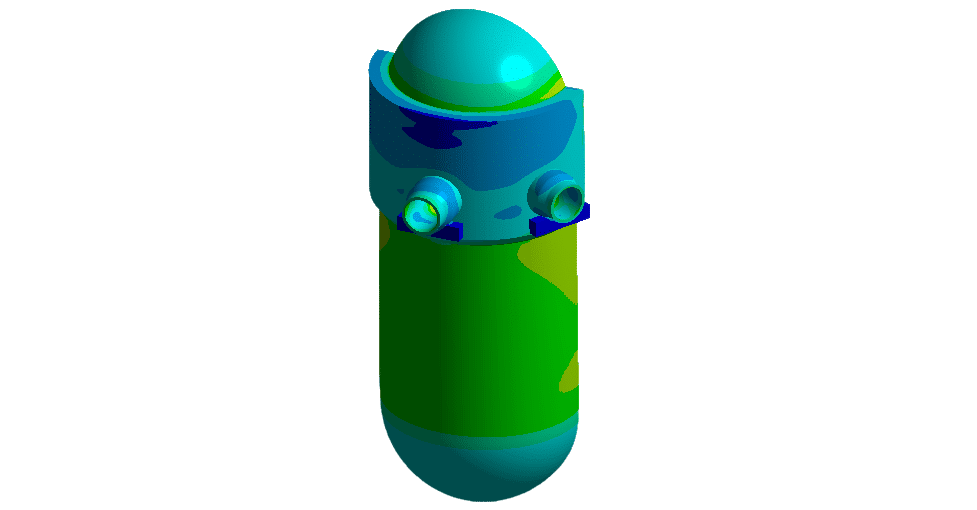

All the components of a water reactor. Description and modelling of vessels, including the porous approach, thermal and turbulence effects. RCC-M mechanical design.

Irradiation devices

Thermohydraulic and thermomechanical simulations. Modelling of radiation and heat sources. Vibration and seismic calculations. RCC-MRx dimensioning.

Experimental reactor

Thermal-hydraulic, thermomechanical and vibration studies on complex assemblies for the RJH reactors and the ITER project. SDC-IC, RCC-MRx sizing.

Experimental nuclear facility

Simulation of experimental nuclear facilities. Benchmarking, safety analysis.

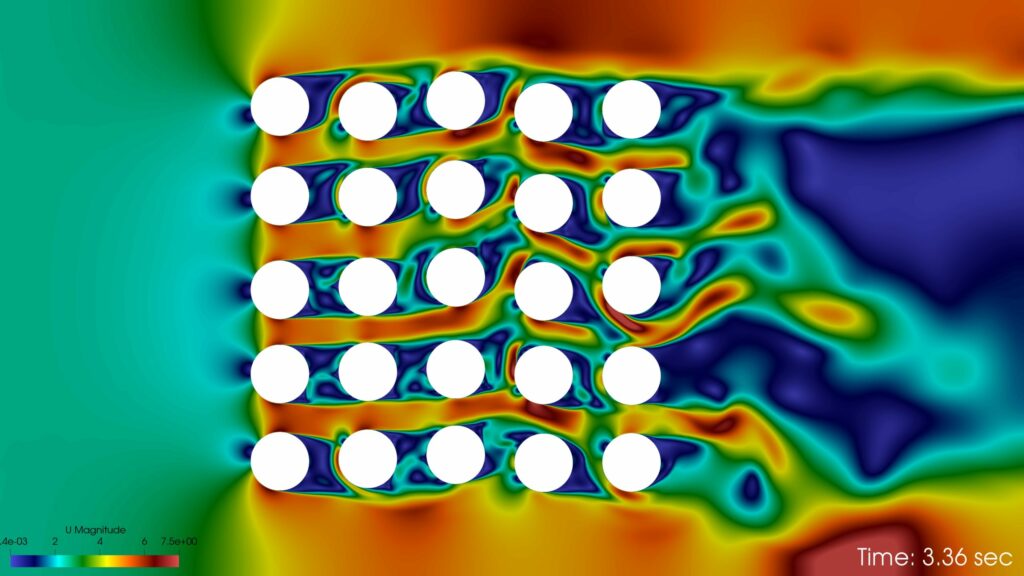

Steam generator and heat exchangers

Simulations of steam generators, heat exchangers or tube bundles. Porous medium approach, directional pressure drop. Phase change.

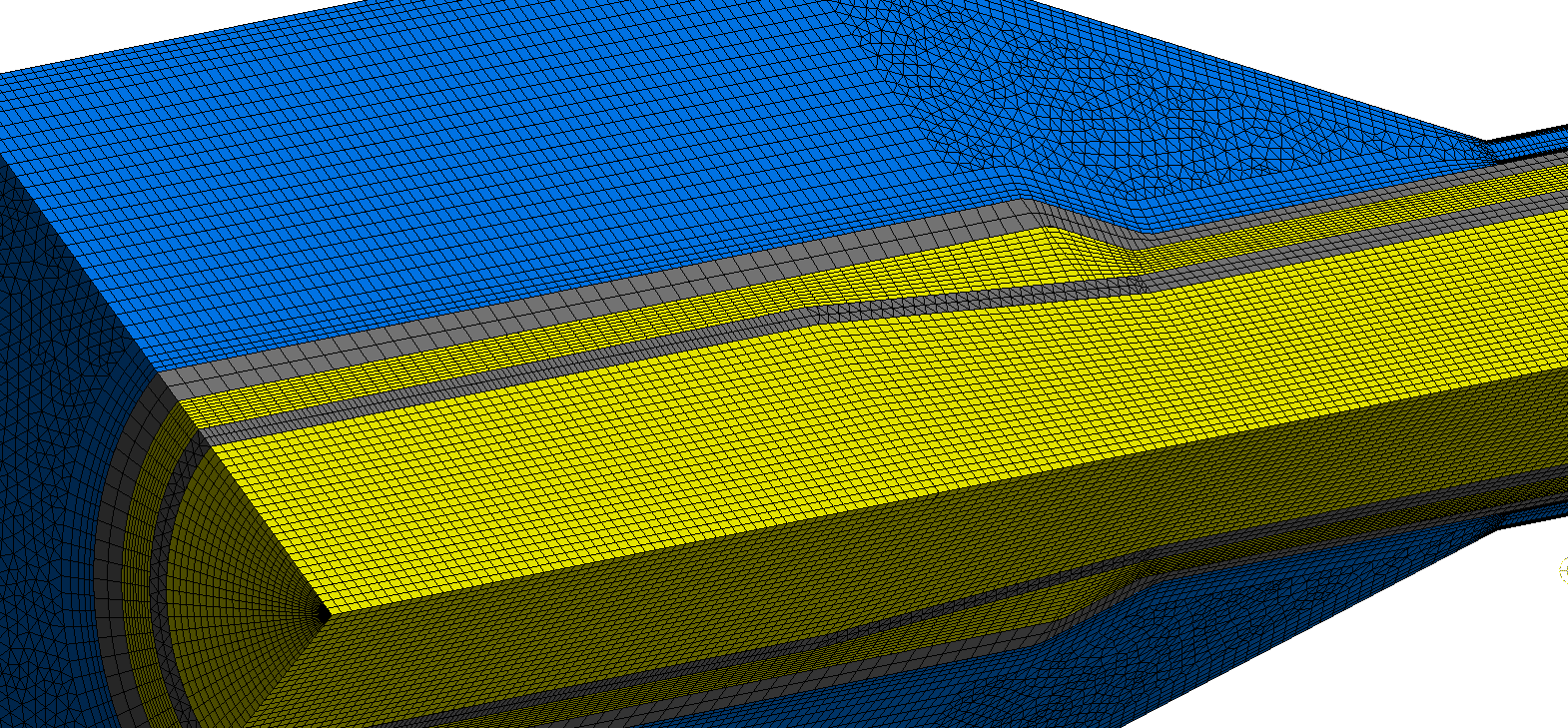

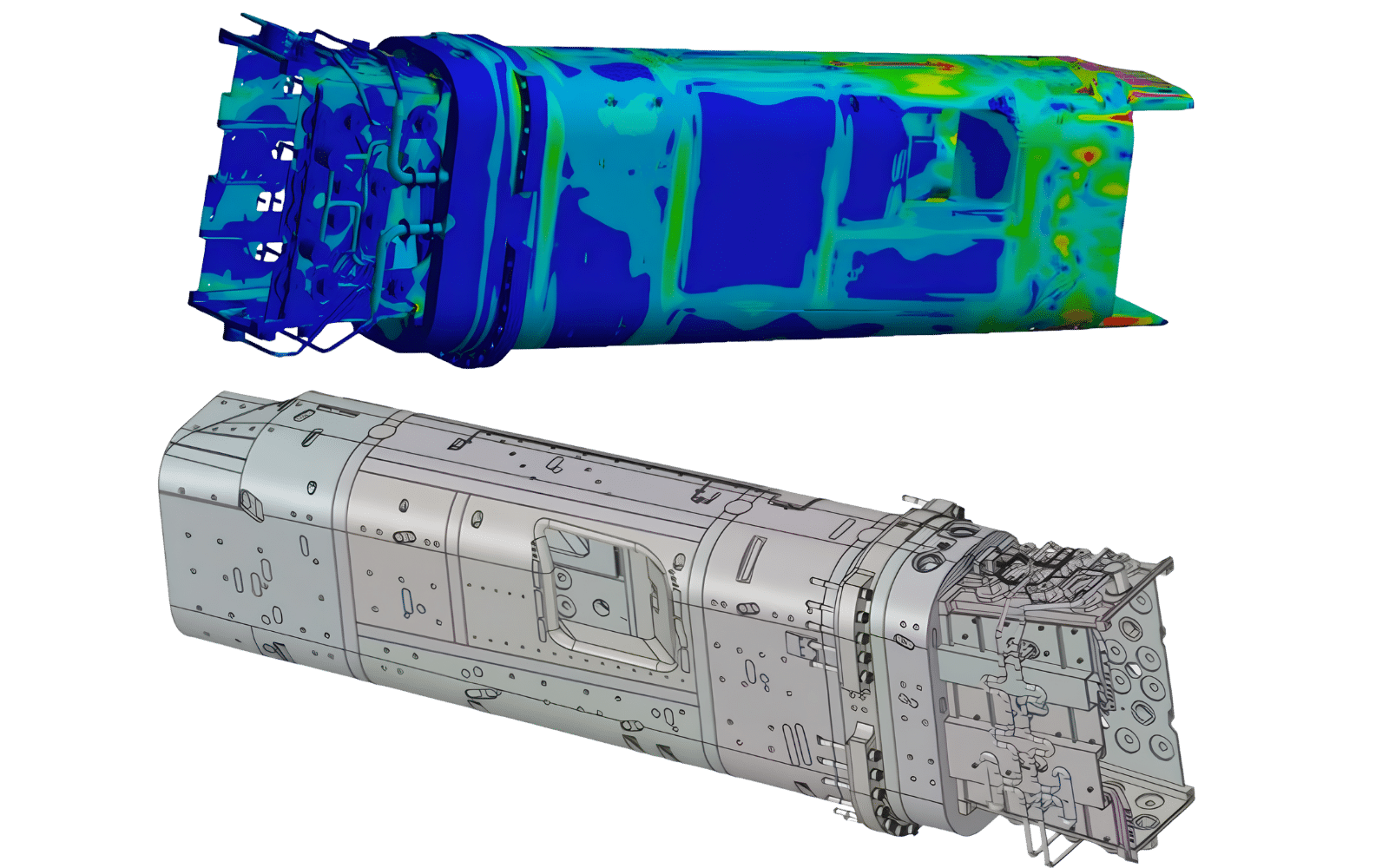

Thermomechanical and seismic design of complex cooling systems for the ITER project

This study illustrates an example of a mechanical design application for the nuclear industry involving the use of industry standard codes (RCC-MRx and SDC-IC). The particularity of the study stems from its complexity, with multiple types of loading taken into account (thermal fields from previous CFD studies, pressure, electromagnetic forces, earthquake, imposed displacements and prestressing) on a complex finite element model (350 assembled components; mesh of 30 million nodes) and the modelling of non-linear physics (contacts/friction, temperature dependence of mechanical properties).

Practical applications in the nuclear environment

Our advanced simulations meet the most stringent requirements of the nuclear sector. Using CFD and structural modelling, we support our customers in the analysis of critical scenarios.

Nuclear storage pool during an earthquake

This video illustrates an example of sloshing simulation in the case of a nuclear fuel storage pool subjected to an earthquake.

The accelerogram used in this simulation is a fixed one, so the results obtained are purely illustrative.

The underlying aim is to calculate the forces on the concrete walls in order to check the design of the civil engineering.

The simulation is carried out using marineFoam, a VoF / GFM solver developed under one of our favourite tools: OpenFOAM.

Nuclear storage pool during an earthquake

This video illustrates an example of sloshing simulation in the case of a nuclear fuel storage pool subjected to an earthquake.

The accelerogram used in this simulation is fixed and the results obtained are therefore purely illustrative.

The underlying aim is to calculate the forces on the concrete walls in order to check the design of the civil engineering.

The simulation is carried out using marineFoam, a VoF / GFM solver developed under one of our favourite tools: OpenFOAM.

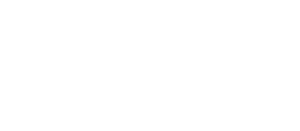

REP - Thermomechanical study

This video illustrates a typical calculation carried out for the nuclear industry. The vessel in question is a PWR pressure vessel. The calculations are thermomechanical. The dimensioning of this type of component is carried out using the normative codes relating to the nuclear sector: the RCC-M. The principle is to check the design of the structure against a number of criteria to guard against many types of damage: excessive deformation, plastic instability, elastic and elastoplastic instability, progressive deformation or fatigue, etc.

Thermomechanical transient of a neutron source

The nuclear requirement, our daily business

We support nuclear industry players in their most critical projects, ensuring compliance with the strictest calculation codes (RCC-M, ASME, etc.).