Other sectors

Initially recognised for our expertise in the nuclear sector, we have extended our know-how to many other fields, bringing innovative, high-performance solutions to our customers.

Simulation digital for industry

We carry out all kinds of numerical simulations for applications involving flow, mechanical stress or temperature fields.

Improving overall performance

Numerical simulation is used to anticipate and optimise the behaviour of systems subjected to fluid flow, mechanical stress or heat exchange. It helps maximise the reliability and efficiency of industrial designs.

Speeding up time to market

By reducing the need for physical prototypes and exploring multiple virtual design scenarios, simulation shortens development cycles and limits the costs associated with experimental testing.

Expertise and reliability

With over 10 years' experience and hundreds of projects under our belt, we have proven our ability to manage complex studies and deliver reliable results. Our team of experienced engineers is on hand to support you at every stage of your project, from initial design to final validation.

Improving overall performance

Numerical simulation is used to anticipate and optimise the behaviour of systems subjected to fluid flow, mechanical stress or heat exchange. It helps maximise the reliability and efficiency of industrial designs.

Speeding up time to market

By reducing the need for physical prototypes and exploring multiple virtual design scenarios, simulation shortens development cycles and limits the costs associated with experimental testing.

Expertise and reliability

With over 10 years' experience and hundreds of projects under our belt, we have proven our ability to manage complex studies and deliver reliable results. Our team of experienced engineers is on hand to support you at every stage of your project, from initial design to final validation.

Fluid mechanics and CFD

CFD (Computational Fluid Dynamics) is a powerful tool for analysing and optimising fluid flows in a variety of industrial applications. By numerically simulating the complex interactions between fluids and structures, we can identify areas of turbulence, improve aerodynamics and optimise cooling or ventilation systems. Whether you are in the aerospace, automotive, energy or construction industries, our CFD simulations enable you to design products that perform better, are more efficient and last longer.

Structural mechanics and finite element analysis

Structural finite element calculations are essential to guarantee the reliability and durability of your products under a wide range of mechanical stresses. By accurately modelling the behaviour of materials and assemblies, we can predict weak points, optimise designs and ensure compliance with safety standards. Whether it's for complex structures in the nuclear industry, critical components in aeronautics or infrastructure in construction, our finite element analyses give you a detailed view of performance.

structure.

Concrete cases for a variety of industrial challenges

Whether it's a question of mechanical components, equipment subject to extreme stress or energy optimisation, each study is designed to meet a specific need in terms of performance, safety or innovation.

Flexible coupling

Flexible couplings are used to transmit torque between two shafts. They are mainly used to compensate for misalignment between shafts and to attenuate vibrations, shocks and jolts, or to accommodate thermal expansion due to overheating. In addition, structural mechanics simulation can be used to calculate the level of stress experienced by this type of mechanism, and to provide, for example, a maximum torque value that must not be exceeded.

CFD simulation of a wind turbine

Thermomechanical study of a spark plug

Cavitation in a hydrodynamic bearing

Bearings are one of the most widely used mechanical components. However, cavitation is a complex physical phenomenon and can be a major problem. Cavitation can cause surface erosion and weaken the bearing, leading to potential failure.

Cavitation can be studied and analysed by CFD, providing knowledge of the cause of the cavitation. In addition, the study of the flow in the bearing, taking into account the phase change, can be carried out by numerical simulation, taking into account 3D effects.

Cavitation in a hydrodynamic bearing

Bearings are one of the most widely used mechanical components. However, cavitation is a complex physical phenomenon and can be a major problem. Cavitation can cause surface erosion and weaken the bearing, leading to potential failure.

Cavitation can be studied and analysed by CFD, providing knowledge of the cause of the cavitation. In addition, the study of the flow in the bearing, taking into account the phase change, can be carried out by numerical simulation, taking into account 3D effects.

Centrifugal pump

Computational Fluid Dynamics (CFD) is a valuable tool for simulating and analysing pump behaviour. Using CFD, engineers can model the flow of fluid through a pump, enabling the complex interactions between pump components and the fluid to be visualised and understood. This includes the analysis of velocity profiles, pressures, turbulence and energy losses, which are crucial in assessing the performance and efficiency of a pump. CFD can also identify areas of recirculation, cavitation and other undesirable phenomena that can affect pump durability and reliability. By optimising pump design through CFD simulation, engineers can reduce development costs, improve energy efficiency and extend equipment life.

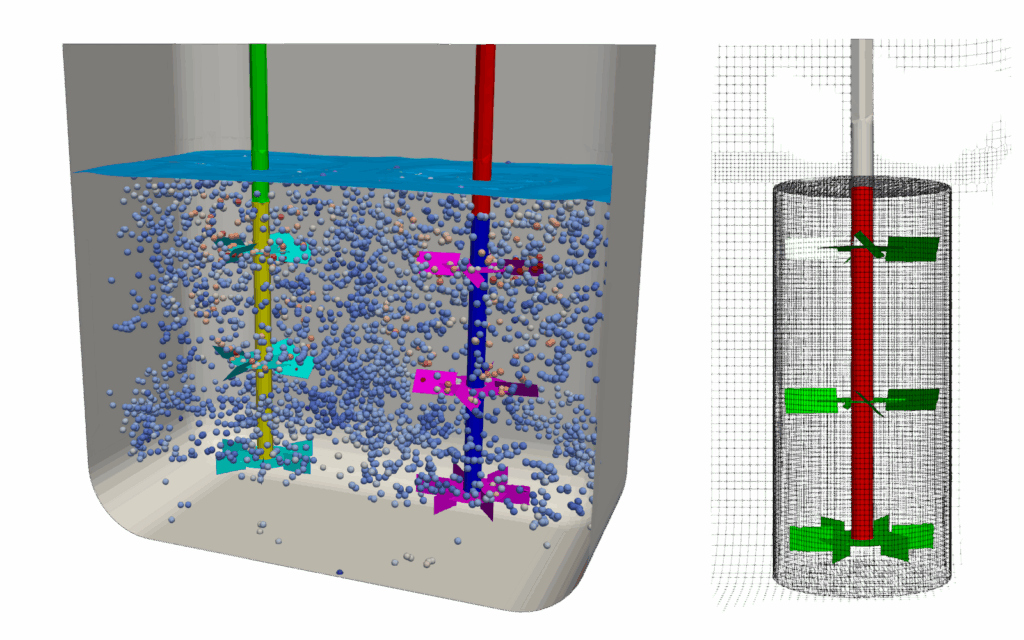

Simulation of a mixer

Over the last decade, Computational Fluid Dynamics (CFD) has become an essential tool for solving problems in various industrial sectors such as the pharmaceutical industry, oil and gas and chemical processes. Mixing applications are widely used in many industrial fields.

The CFD approach can be used to evaluate key mixer parameters such as mixing time, local species concentration or flow characteristics. CFD is also very useful for testing various vessel or rotor shape designs.

You wish to contact us and talk to an expert?

Tell us about your project, your needs or your technical challenges. A G-MET Ingénierie expert will get back to you as soon as possible to discuss the most appropriate solutions.