Structural mechanics

Assess and improve the strength of components to guarantee their integrity under mechanical loads

Varied skills in structural mechanics

The use of numerical simulation for structural studies has become essential, making it possible to simulate a variety of physical phenomena in increasingly complex structures.

The standard mechanical design codes set out the types of damage to be analysed and the associated verification criteria, which depend on the sector concerned and the structure being studied.

Mastery of physics, standards codes and simulation software is essential for the successful completion of a mechanical study.

Seismic

Thermomechanics

Dynamics

Fatigue

Friction, plasticity and large displacements

Seismic

Thermomechanics

Dynamics

Fatigue

Friction, plasticity and large displacements

Advanced calculation tools

With our in-depth expertise in ANSYS Mechanical, it is now our tool of choice for carrying out the most complex projects.

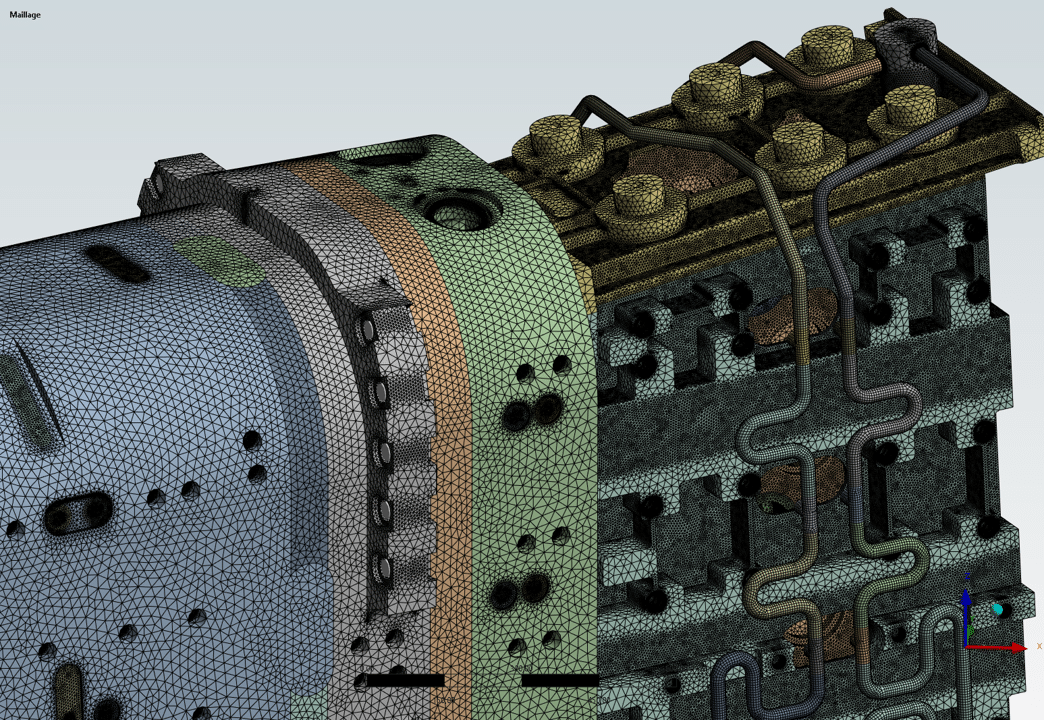

We are equipped with a 32-core computing machine with 512 GB of RAM, enabling us to develop highly complex finite element models, with several hundred components, leading to meshes of several tens of millions of nodes.

Python is now an essential tool for pre- and post-processing, integrating seamlessly with ANSYS, enabling us to create bespoke applications (data preparation programs, post-processing according to dimensioning codes, etc.).

Controlling dimensioning codes mechanical

Thanks to our in-depth knowledge of calculation codes (RCC-M, ASME, Eurocode, EN13445, etc.), we can ensure that our studies comply with the most stringent regulatory and standards requirements.

RCC-M

RCC-MRX

SDC-IC

EUROCODES

CODAP

EN 13445

FEM

EN 13001

EN 13480

A step-by-step study of structural mechanics

Stage 1

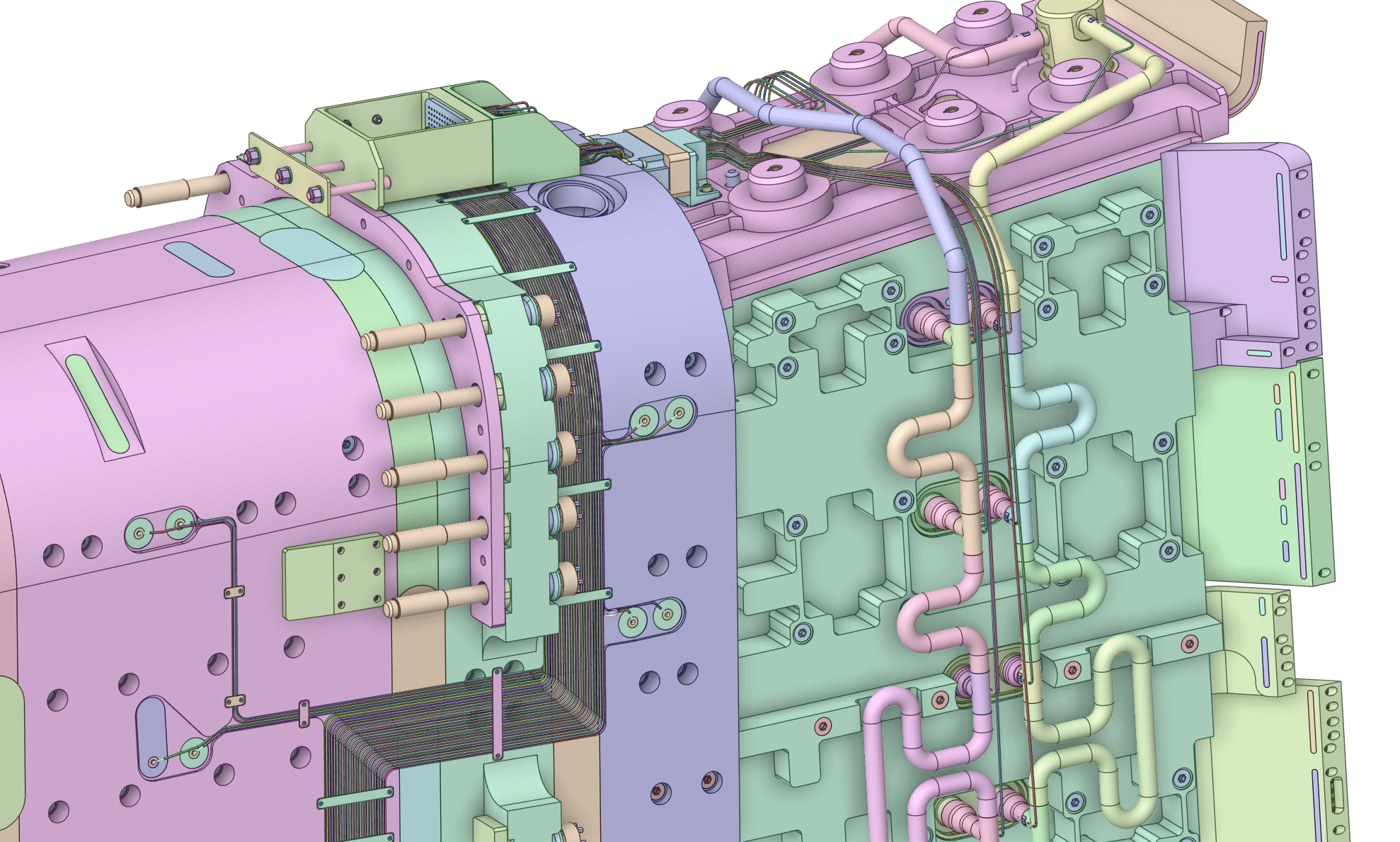

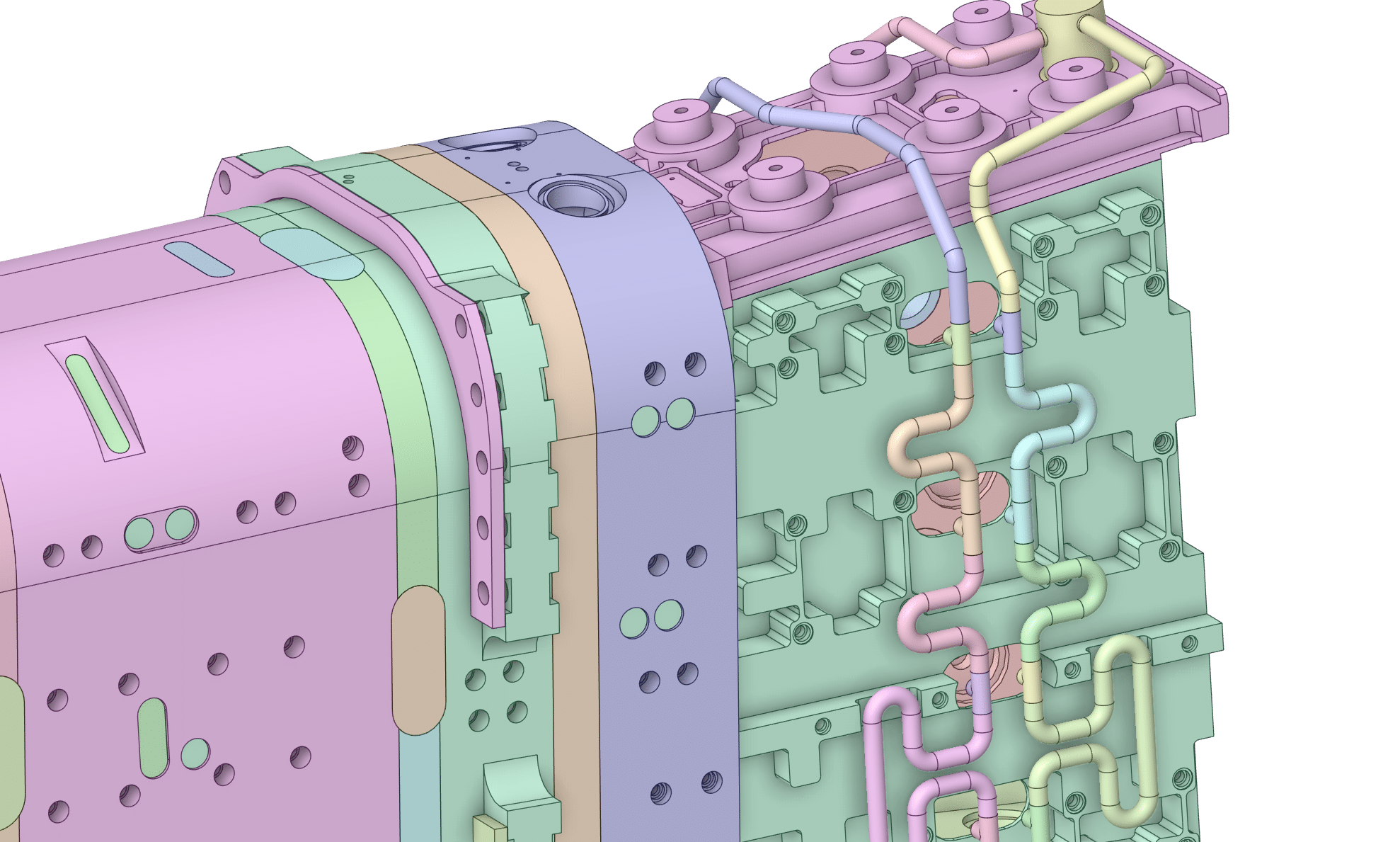

Receipt of study geometry prepared by a customer using design software (CAD). The most common format transmitted is a step file (.stp) or a drawing if no CAD is available.

A step-by-step study of structural mechanics

Stage 2

Simplification of CAD in preparation for the meshing stage.

A step-by-step study of structural mechanics

Step 3

Meshing stage to discretise the component geometry.

A step-by-step study of structural mechanics

Step 4

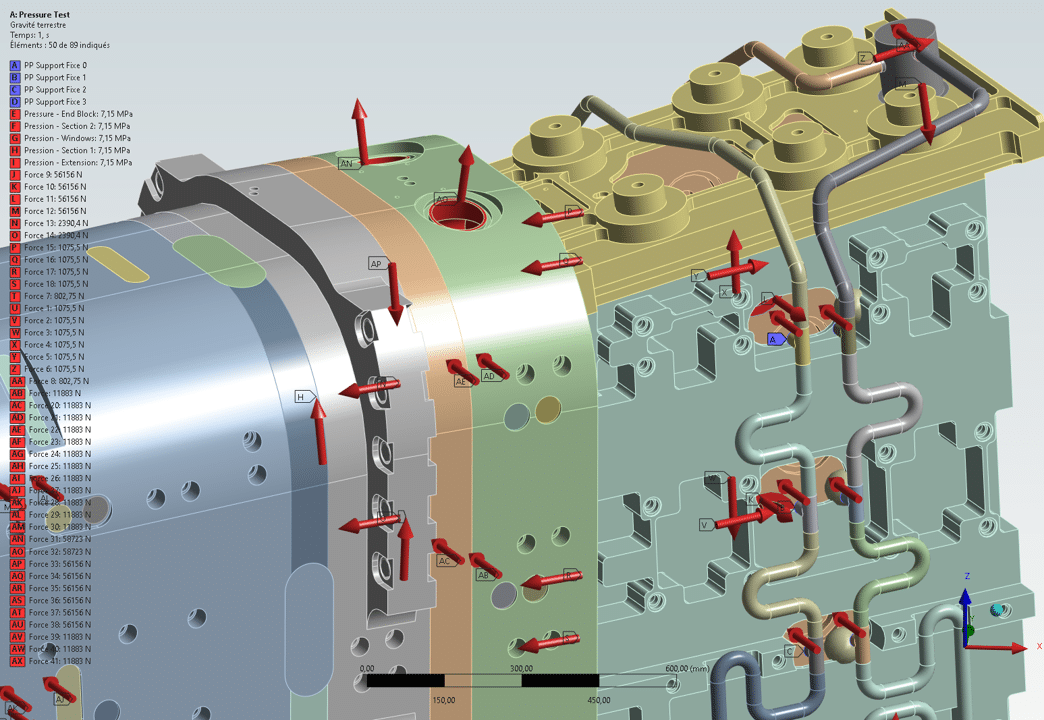

Definition of mechanical boundary conditions, connections between components and mechanical loads

A step-by-step study of structural mechanics

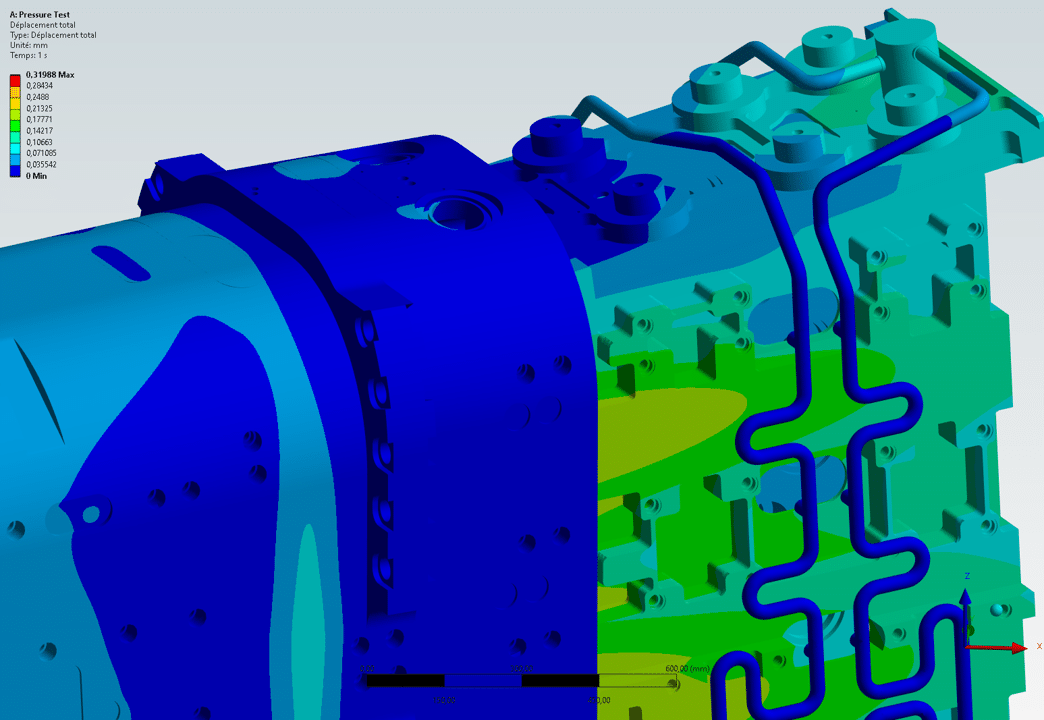

Step 5

Calculation and post-processing of results (stress fields, displacements, forces in connections, at anchors, etc.). Comparison with permissible values.

A step-by-step study of structural mechanics

Step 6

Drafting of a calculation report presenting all of the above

the assumptions and results of the study.

They make us trust

Expertise that guarantees the reliability, safety and durability of your mechanical equipment, whatever your sector of activity.

Sylvain. P

ARKADIA GROUP

A professional, responsive and committed team whose work is always of the highest quality.

Anass. E

ITER

It was a real pleasure to work with G-MET for several years on the Duct Liners project, one of the most complex components of the ITER installation. The quality of their CFD analyses, of the blow moulding for the drainage (developed under openFOAM), and of the thermomechanical analyses, far exceeded our expectations. Their highly qualified, responsive and solution-oriented team is a real asset to the project.

Sylvain. P

Arkagia group

A professional, responsive and committed team whose work is always of the highest quality

Anass. E

Iter

It has been a real pleasure to work with G-MET for several years on the Duct Liners project, one of the most complex components of the ITER installation. The quality of their CFD analyses, the blowing for the drainage (developed under OpenFOAM), as well as the thermomechanical analyses, far exceeded our expectations. The highly qualified, responsive and solution-oriented team is a real asset to the project.

Concrete cases for a variety of industrial challenges

Whether it's a question of mechanical components, equipment subject to extreme stress or energy optimisation, each study is designed to meet a specific need in terms of performance, safety or innovation.

Seismic

G-MET carries out seismic dimensioning using various methods: equivalent statics, spectral modal analysis or, exceptionally, transient analysis. These calculations apply to new equipment as well as to existing installations in the context of reverse engineering, particularly when regulatory requirements in terms of seismicity change.

The equipment we handle is extremely varied, ranging from simple structures such as cable tray supports, ventilation ducts or technical networks, to complex assemblies such as glove boxes or specific, highly technical mechanical components.

Pressurised equipment

Pressure equipment is ubiquitous in the mechanical industry, and is used in many industrial sectors. Examples include heat exchangers, piping networks and pressurisers. Such equipment is frequently subjected to significant thermal gradients, requiring precise thermomechanical calculations to guarantee its integrity and regulatory compliance.

Lifting

Lifting systems are commonly used in industry, whether for handling heavy loads, assembling structures or moving sensitive equipment. These devices can include hoists, jib cranes, overhead travelling cranes, jacks or articulated mechanisms, and sometimes feature highly complex mechanical configurations.

In some cases, their modelling requires the integration of non-linear physical phenomena, such as dry friction, mechanical clearances or large displacements. An advanced finite element approach can then be used to accurately simulate their in-service behaviour, taking into account dynamic stresses, multi-body interactions and possible failure conditions.

Let's talk for your simulation projects

Do you have a question or a specific need? Leave us a message and our team will get back to you as soon as possible to discuss the best technical solutions.